Our clients count on us to supply a diverse range of flame lamination products across our many markets. Our products can be found in a wide array of markets and applications including cleanroom wipes, automotive seats, yacht interiors, locomotive seating, instrument cases, orthopedic braces, and countless other applications.

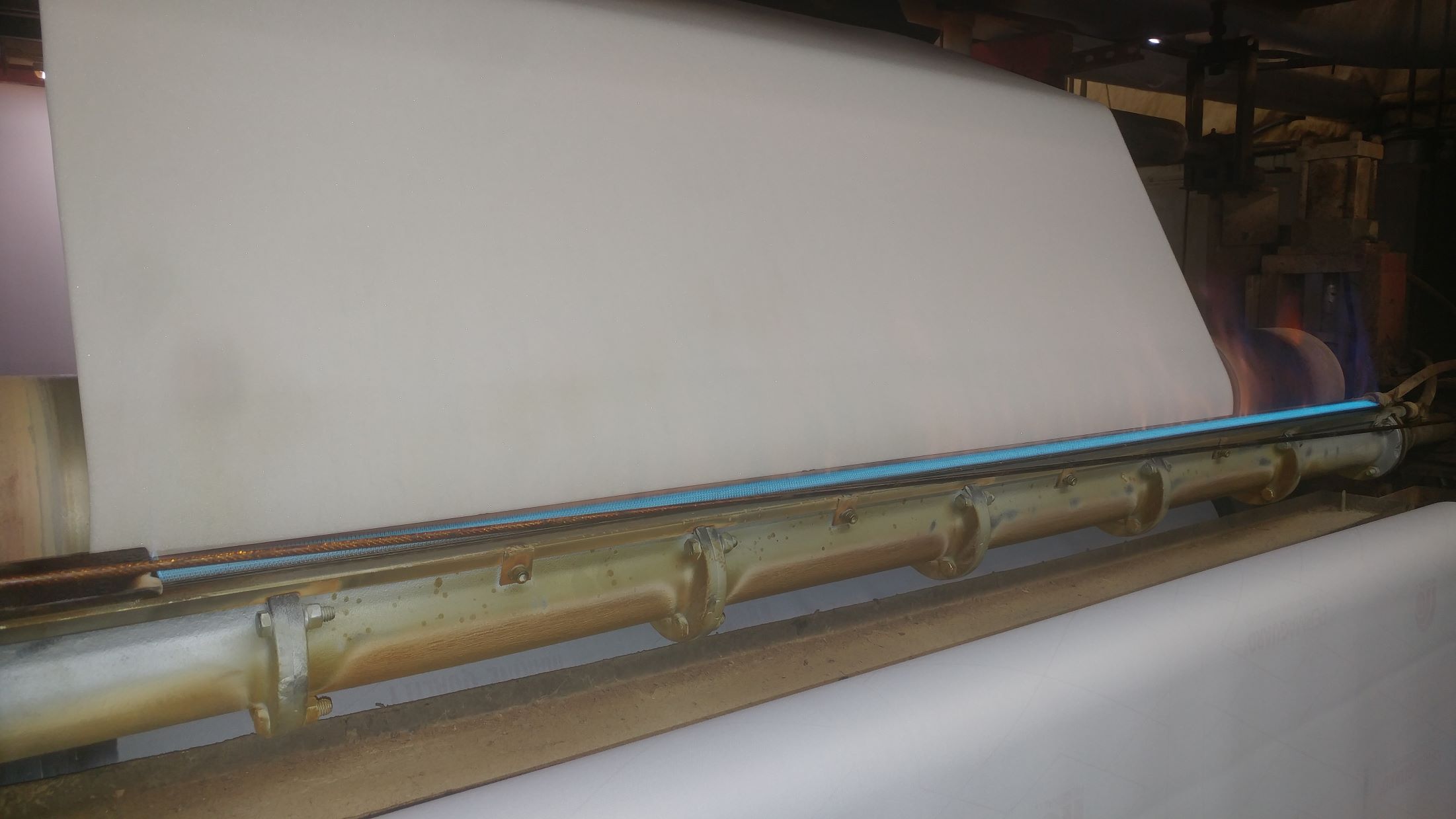

We apply our unequalled expertise to bond all sorts of substrates together using our matchless flame lamination process. Some of the raw materials used in our laminated composites are:

- knit, woven and nonwoven fabrics

- films

- foils

- pressure sensitive and heat activated adhesives

- vinyl

- carpet

- plastic

- a wide array of foams including polyether and polyester

Once combined, we turn these materials into much sought-after composites. Depending on the application, our composites may range from two components to as many as six or more. Our process is often called upon to extend the life of the individual components, or it may provide superior technical performance as required in molding, acoustic or foam-in-place applications. In other cases, our customers simply need two substrates bonded together.

From car seats and headliners to medical braces, lingerie and carpet, we consistently produce high-quality, low-cost flame lamination products that our customers have long relied upon.